Constant luminous flux for long LED light lines.

Our LED Strips in the endurance test.

With linear LED strips, beautiful homogeneous light can be realised for many applications. However, it must be ensured that the LEDs are supplied with sufficient voltage over the length of the strips. Otherwise, the emitted light loses brightness towards the end of the module.

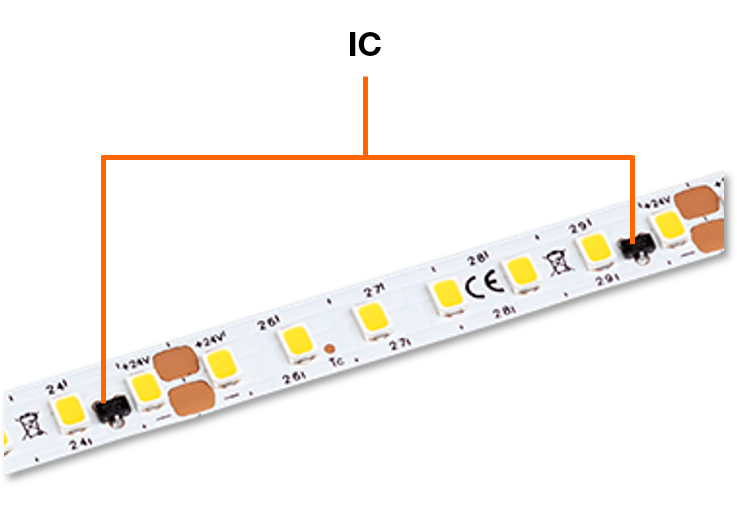

In order to counteract such decreases in luminous flux, so-called "ICs" ("Integrated Circuits") can be used instead of the otherwise common resistors on the LED strips. This is called constant luminous flux technology, which Radium also uses as standard in the production of LED Star Strips. Whether an IC or a resistor is soldered on is difficult to recognise at first glance - especially for laymen. Depending on the manufacturer, there are different identification features, such as the number of solder joints.

But what is the technical difference between an IC and a resistor?

In theory, it can be roughly stated:

Most LED strips are usually equipped with resistors. These resistors set a static operating point of the LEDs at nominal voltage. However, the resistor cannot compensate for a voltage drop over the length of the LED strip, so that the LEDs become darker with greater distance from the electrical supply.

In higher-quality strips, ICs are often attached to the conductor track instead of – or in addition to – the resistors. These tiny circuits are current regulators that supply LEDs with the correct operating current and keep it at a constant level even if the voltage varies slightly. So, voltage drops can be compensated by these ICs within a certain voltage range. As a result, the LED module glows homogeneously at the same brightness even over longer lengths. This constant luminous flux technology is also gentler on the LEDs because it also protects the LEDs from overvoltage during operation.

We have done the test:

Is it really a visible difference whether an LED strip is operated with a resistor or with an IC?

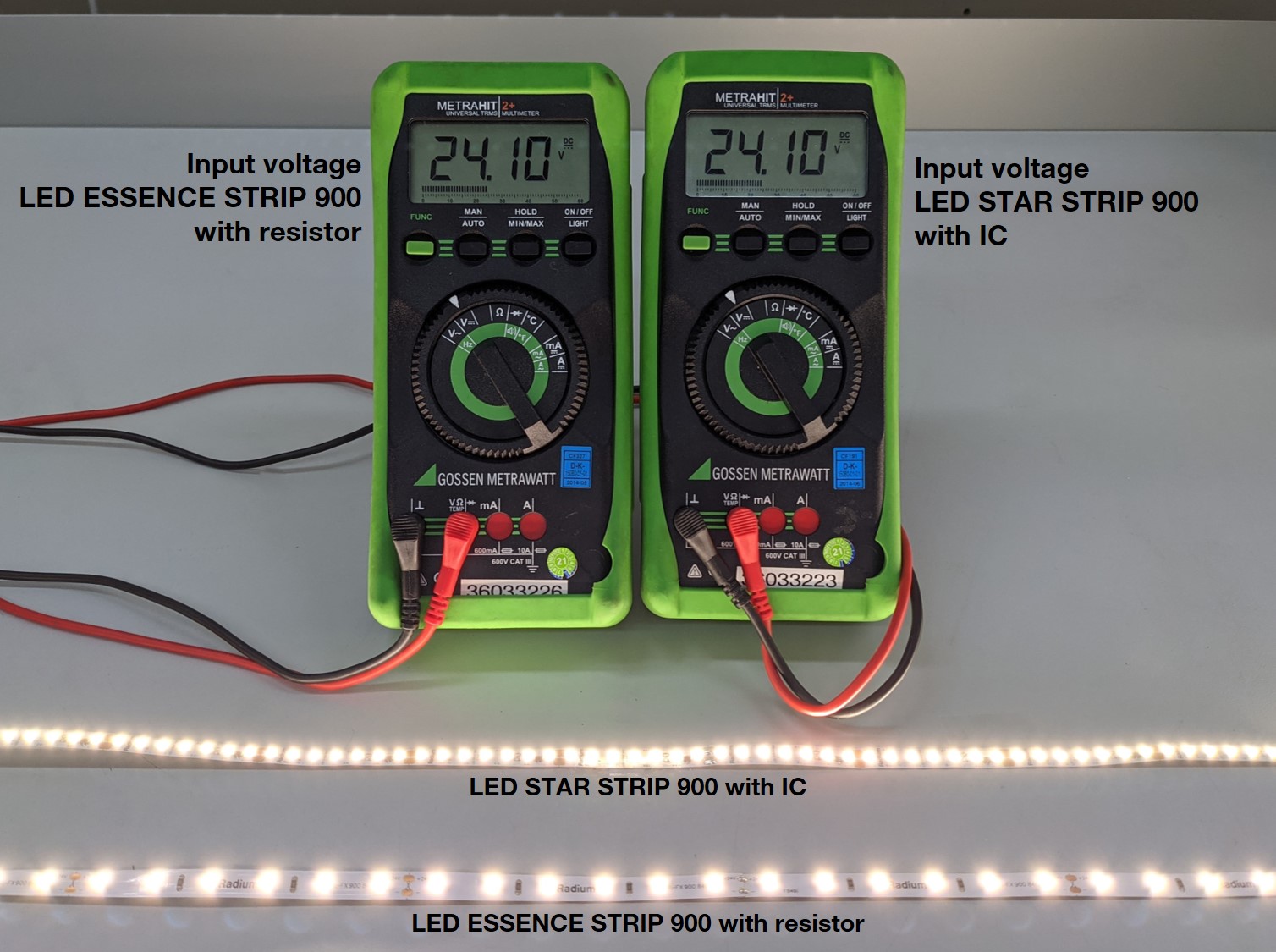

For this purpose, we used two of our LED strips for the test and measured their luminous intensity curve at a length of 10 metres each. We chose the LED Star Strip 900 with constant luminous flux technology (IC) and the LED Essence Strip 900, which is operated with resistors.

Test setup

First, the input voltage of both modules was measured immediately after current injection, followed by a measurement of the voltage at the opposite end of the 10 metre long LED strips (denoted here: residual voltage).

The input voltage was 24.10 V for both strips.

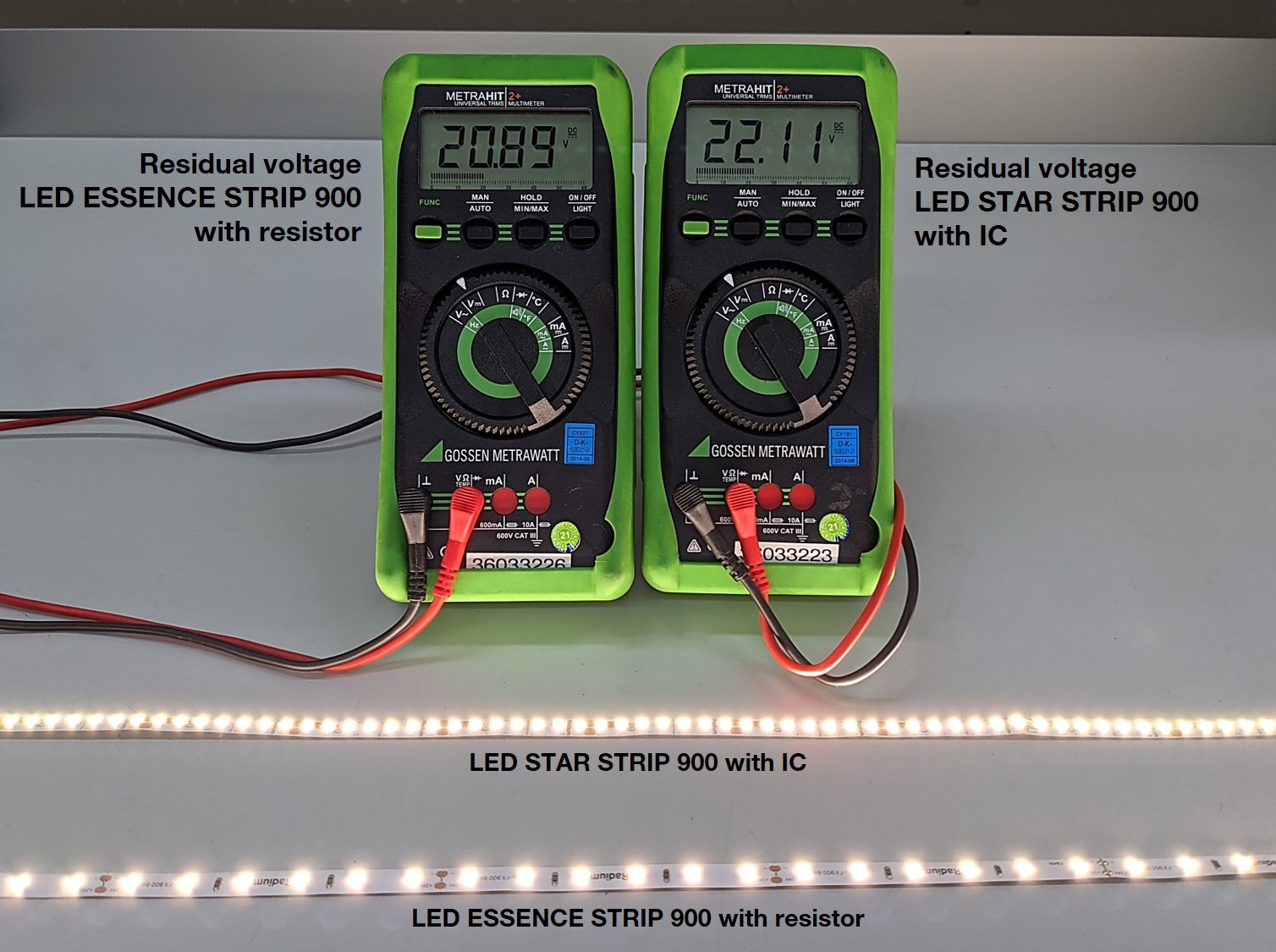

The residual voltage was 22.11 V for the LED Star Strip and only 20.89 V for the LED Essence Strip. However, this cannot be attributed to the resistors and ICs, but rather to the different thicknesses of the copper conductors. In the case of the LED Star Strip, this is particularly thick and therefore also conducts the current more lossless.

The voltage drop that occurs depending on the length of the LED strips is supposed to be compensated by the IC. The results of our luminous flux measurement in the integrating sphere show with how much success this works compared to the resistance.

At an input voltage of 24.10 V, the luminous flux of both LED strips is around 900 lumens per metre.

Our test clearly shows that the luminous flux of the strip with resistor drops so much that after 10 metres at 20.89 V only less than 600 lm/m are emitted. The LED strip is therefore not suitable for operation for 10 metres (or more) at a stretch.

The LED Strip with constant luminous flux technology delivers almost the same brightness over the entire length despite the voltage drop to 22.11 V. The diagram shows that the IC can keep the luminous flux constant even when the voltage drops to as low as 21.5 V.

Conclusion

Based on our measurement results, we can see that the luminous flux of an LED strip with resistors decreases with increasing distance from the electrical feed. A difference in luminous flux of less than 10% is hardly visible to the human eye and poses no problems in application. To ensure a sufficiently constant brightness with a luminous flux decrease of less than 10%, the maximum operable length of our LED Essence Strip 900 is 5 metres.

With the LED Star Strip 900, on the other hand, things are different: thanks to the ICs and the thicker conductor path, the luminous flux is kept at a uniform level over a greater distance. This means that even a whole 13 metres of the module can be operated in one piece without any loss of brightness.

To answer our question posed in advance:

Yes, there is a visible difference whether an LED strip is operated with a resistor or with an IC. This difference is noticeable in the brightness of the LED strip after a certain operating time. This in turn is the reason why a maximum operable length is recommended for LED strips.

Our hint for even longer light lines

For particularly long, continuous lines of light, you can feed your LED Strip in on both sides or even from the middle. You can find out how this works in this one of our articles.